We can’t imagine life without plastic. It is cheap and has many practical characteristics – it is lightweight and flexible, corrosion and chemical resistant, long-lasting and easy to make, whether colourless or in any colour. Plastic is simply wonderful and replaces natural materials, such as metal, stone and wood. Because of these advantages, more and more plastic is being manufactured all over the world. But this inevitably means that more plastic waste is also created.

The struggling oceans

Not all countries handle their plastic waste responsibly, so a lot of the waste ends up in the oceans and seas. We would currently be able to find hundreds of millions of tonnes of plastic waste in them, with a further 5 to 13 million tonnes added each year. Islands of floating plastic waste threaten life in the seas. This plastic also gets into our bodies through fish and marine animals and threatens our health.

The vision

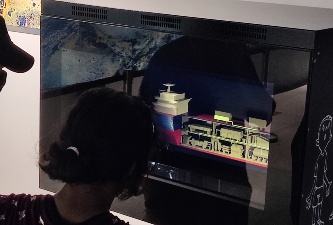

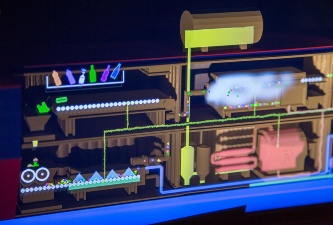

There are many proposals for ridding the oceans of plastic waste. A great number of these focus on procedures for finding the waste, fishing it out and removing it to the mainland for further processing. Our concept is based on a ship that processes the waste directly on the open sea, where it is transformed into useful raw materials and heat. It then takes the produced materials together with the unprocessed waste to the coast in order to return to another floating island of plastic waste.

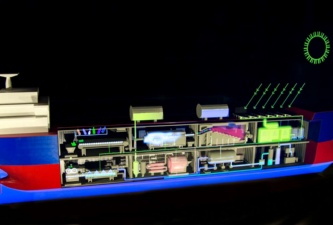

The ship uses the same technology as used on land and looks like a regular ship for the transport of standard containers used in maritime shipping throughout the world. The equipment for processing the plastic is located in containers inside the body of the ship. The containers are mutually connected and the processed waste passes through one container to another. The energy obtained by the thermal processing of part of the plastic waste is used to power the ship’s engines and all the equipment on the ship.

How it works

The fished-out plastic waste is first sorted on the ship and prepared for waste-to-energy treatment according to the quality and degree of degradation (plastic degrades in the ocean over time until it is no longer possible to recycle it). The higher-quality waste is processed through pyrolysis, which is the decomposition of organic material through the application of heat in the absence of air. The result of pyrolysis is pyrolysis oil, which can be used on land as fuel or as a raw material in the petrochemical industry. It can also be used right on the ship as fuel for the motors. Gas and solids are also created during the production of pyrolysis oil. They can be used to heat the pyrolysis units. Low-quality waste that is degraded or contaminated is burned. The resulting heat is used primarily for the desalination of sea water on the principle of evaporation. The desalination results in both distilled water, which is taken to the mainland as a finished product, and the remaining sea water with a high salt content. This water is stripped of harmful microplastics and returned to the sea.

Because there is enough room for supporting technologies, such as search drones, containment booms for the removal of waste or even smaller boats for waste collection, the ship can operate at any distance from the coast. Upon its return, it just has to unload the barrels of desalinated water, pyrolysis oil and a small amount of solid waste.

The proposed technologies are a combination of best practices and they can also be used successfully on land.

Ing. Michal Šyc, Ph.D.

Institute of Chemical Process Fundamentals of the CAS

Deputy Director for Economy, Head of Department, Senior Researcher

E-mail: syc@icpf.cas.cz